Build a digitally connected ecosystem with Schneider Electric's Harmony Hub

Ask for a demonstration and experience the benefits and possibilities!

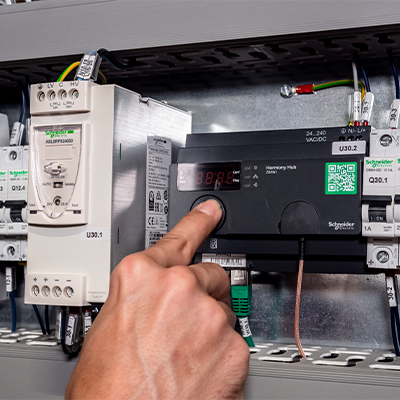

Harmony Hub is a wireless system based on the generic ZigBee communication protocol for your existing industrial plants and processes. Collect concrete signals from a control panel and generate data via wireless components such as limit switches, push buttons and sensors.

Data collection via the Harmony Hub

With the Harmony Hub, you can link up to 60 different wireless components. Easily connect wireless push buttons, sensors or pull cord switches. Through the Harmony Hub, you build a connected ecosystem with wireless products that work together, generate data and offer new insights. This makes it possible to quickly monitor machines or locate pressed emergency stop buttons, for example. With the Harmony Hub, you build a digitally connected ecosystem in a way never before possible.

Wireless control with the Harmony Hub

The Harmony Hub goes beyond data generation, making industrial processes more efficient and flexible. Wireless connectivity allows operators to operate machines remotely faster and more efficiently. Dangerous situations are also avoided by eliminating cabling. This enables operators to do their work at a safer distance. In short, Harmony Hub ensures speed, full mobility and flexibility of your industrial applications.

Getting started with Harmony Hub yourself?

Would you like to experience the benefits and capabilities of Harmony Hub for yourself? Then request a demonstration by filling in the form below. During the demonstration, we will show you how to simplify the control of your equipment with wireless connectivity. You will also get information on how the solutions contribute to cost savings, time savings and improved safety in the workplace. Fill in the form and we will contact you as soon as possible!

Yes, I would like a demonstration of the Harmony Hub

Stay up to date with the latest news:

-

Schneider Electric - Modicon Edge I/O NTSRead moreModicon Edge I/O NTS, Schneider Electric’s latest IP20 distributed I/O system, is more than just an input/output system. It is designed to equip machine builders, system integrators, and industrial end-users with the tools they need to thrive in an increasingly data-driven digital world. The system's ability to aggregate and securely share data enables smarter decision-making and improved operational performance. With open Ethernet protocols for connectivity with a wide variety of devices and architectures, OPC UA technology for secure communication and interoperability, and built-in hardware cybersecurity, Modicon Edge I/O NTS helps ensure connectivity, performance, availability, and enhanced network security. Furthermore, the system complies with current cybersecurity regulations, enabling end-users to safely access and fully leverage their data — boosting industrial efficiency, flexibility, sustainability, and profitability.

-

Niedax - MTCRead moreThe Niedax MTC is a strong and stable click-on wire mesh tray available in various designs and shapes. Thanks to its unique integrated coupling system, the different sections can be quickly and easily clicked together.

-

News - Siemens - SIRIUS 8WD46 signal columnRead moreHigh system availability and efficient engineering with this flexible signal column. Each segment individually configurable. Siemens has further expanded its portfolio of SIRIUS 8WD4 signal columns with a new high-performance signal column, which is electronically configurable as standard. Making it particularly easy to adapt to individual application requirements.

-

Deep dive Smart Supply about itsmeRead moreThe recent expansion of itsme Group has been noted by the creators of Smart Supply, a US podcast about the tech wholesale industry. Their ‘deep dive’ on itsme was published this week.

Check out our other success stories:

-

TR Service - Future-proof low-voltage panelRead moreTR-Service provides industrial maintenance using all disciplines, from electrical and mechanical to hydraulic and pneumatic. With support from Breemes, the company installed a large low-voltage panel. ‘After discussing my summary plan with them, I decided to just do it,’ says director-owner Raoul Tielens. At Breemes' suggestion, the panel was future-proofed by preparing it for power monitoring.

-

Peeters - Young Company, New EquipmentRead moreSince its founding a few years ago, Peeters Robotic Solutions has been rapidly developing, working on projects both domestically and internationally and providing standard solutions for industrial palletizing. The company stays up to date with the latest technology, including Festo’s electrical and pneumatic drives. To achieve this, it relies on itsme. “Thanks to their expertise and skills, we can bring innovation to the forefront for our customers.”

-

Kusters - Putting weight behind itRead moreKusters was looking for a weighing solution for its banknote devaluation machines that was easy to integrate into the Siemens control system. Through itsme, they came into contact with the right knowledge carriers at Siemens. ‘For us as Kusters, itsme is not only a supplier but also a source of knowledge, with which we co-engineer certain components and process steps, such as this weighing system.’

-

Eneco - Green light for green electricity and steamRead moreEneco Bio Golden Raand, located in the port area of Delfzijl, converts biomass into green electricity and green steam. Each year, the plant processes approximately 300,000 tons of waste wood from the Netherlands and neighboring countries. As part of Eneco’s climate ambitions, a project began in 2022 to replace the existing fluorescent lighting in and around the boiler room. The project was carried out under the supervision of itsme. “Two factors were important in this process: the cost, of course, but also the level of service.”

Why not take a look at these trainings we offer:

-

PROFINET CPNERead moreavailable in Dutch

-

PROFIBUS CPERead moreavailable in Dutch

-

WinCC-SCADA2Read moreavailable in Dutch

-

PCS7-SAFE V9Read moreavailable in Dutch