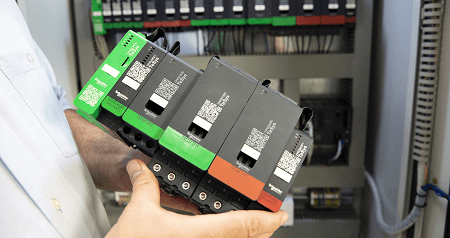

TeSys island

Digital multifunctional load management solution up to 80A

TeSys island is designed to switch, protect, and manage motors and other electrical loads up to 80Amps (AC3) in an electrical control panel.

Features

TeSys™ island is a digital load management solution that makes machines smarter and more reliable. It is a fully digitized, object-oriented load management system and an Industry 4.0 compliant data provider. It reduces machines’ time to market enabling OEMs to move forward in their Industry 4.0 journey. TeSys island gives users easy & remote access to predictive & preventive application data, leading to early diagnostics & maintenance.

Thanks to TeSys island’s object-oriented approach:

- Application selection and system configuration is simplified

- Engineering tasks are automated & reduced,

- Enabling a faster machine installation phase.

In addition, TeSys island supports major automation fieldbuses as EtherNet/IP, Modbus TCP, Profinet and Profibus. It is readily integrated into EcoStruxure™ Machine Expert by Schneider Electric as well as Rockwell’s Studio 5000 and easily integratable into 3rd party TIA portal.

- The system manages motors and other electrical loads up to 80A/37kW/40hp

- Up to 20 modules and 1 bus coupler (up to 112cm length) wide catalog of 30 Avatars ranging from the device level to application level, encapsulates and abstracts the internal logic and let automation experts focus on their application.

- One-click mounting on DIN rail and no need for control wiring on modules

- No auxiliary wiring required, thanks to full connectivity over fieldbus

- All adjustments and setting are digitized, no mechanical dials or dip switches

- Digital & Analog I/Os available

- Different products complaints with international standards (IEC / UL / CSA 61010, IEC / UL / CSA 60947, GB/T14018)

- Only 22 commercial references for the complete system, including 5 standard motor starters and 5 SIL motor starters for functional safety systems as defined in IEC 61508, IEC 62061 and ISO 13849-1

- Energy monitoring at every load as well system level

- Cybersecurity embedded into the system (Achilles Level 2) & compliant to IEC 62443 SDL processes.

- Safe Stop TUV certified (Stop 0 and 1 with wiring categories 1 to 4, suitable for PL c, d, e (Performance Level) and SIL level 2)

- Open connectivity thanks to EtherNet/IP, Modbus TCP, Profinet and Profibus fieldbuses

Benefits

- Featuring a catalog of TeSys Avatars representing load functionalities and basic applications, conceptual to digital twin in Industry 4.0, TeSys island allows intuitive and simplified engineering of machines while reducing time to market

- The object-oriented approach of the TeSys Avatars allows users to focus on machine design, integration, and control, rather than on the selection and commissioning of each electro-mechanical component

- TeSys island eliminates the need for additional inputs and output modules (I/Os) for control

- Users can select the electro-mechanical devices without specific expertise, thanks to the online Motor Control Configurator

- TeSys island is easy to commission through integration with the EcoStruxure Machine Expert engineering suite

- Reduce machine stoppage time with secured remote resets: for a fast and easy restart.

- Faster prescription of spare parts using QR codes and device replacement thanks to embedded functions and SD cards.

You might also be interested in this:

Check out our other success stories:

-

Van Meer - Quick Connection for Energy StorageRead moreDrive specialist Van Meer developed an energy storage system for heavy-duty drives and designed a custom battery system for it. For the connectors in the battery system’s cabinet, their regular supplier itsme recommended omni-brand partner Phoenix Contact. Excellent connectors — only the frame didn’t fit. Phoenix Contact quickly developed a customer-specific connector design. itsme now supplies Van Meer with complete connector sets, including the custom plug.

-

Avebe - A Good Night’s Sleep Thanks to FactoryScanRead moreCompanies often have no clear idea of the installed base of industrial automation in their factories and warehouses. With FactoryScan, itsme can provide an overview of the current status of automation components such as PLCs. Potato processor Royal Avebe uses the results to update their component stock and assess future availability. The scan is intended to reduce the number of hardware-related disruptions Process Control Engineer Johan Wierenga has to deal with. It also helps him sleep better, knowing the stock is up to date.

-

Elektro VV - The right expertise in the right placeRead moreElektro VV, based in the Belgian province of Antwerp, carries out general electrical work and solar panel installations for both companies and private individuals. For complex projects, the company calls on Breemes, which brings expertise such as low-voltage studies. “The challenge is to design a panel that can be built quickly and efficiently, and is future-proof.”

-

OI - Warm relationship with supplierRead moreThe O-I glass factory in Leerdam produces 3.5 million beer bottles every day. The challenge of keeping production running 24/7 is tackled together with trusted supplier itsme. They ensure that technicians never run out of stock during maintenance and that critical components like cables and sensors are heat-resistant. This makes life much more relaxed for supervisor Patrick Maduro and his team in the electrical engineering department.

Why not take a look at these trainings we offer:

-

WinCC-SCADA2Read moreavailable in Dutch

-

PCS7-SAFE V9Read moreavailable in Dutch

-

MIT-IQWORKSRead moreavailable in Dutch

-

PROFINET CPNERead moreavailable in Dutch