text.skipToContent

text.skipToNavigation

Simplified Motion Series consists of different electromechanical components together with a simple and application-optimised combination of motor and servo drives, the so-called integrated drive. This solution does not require an external servo drive. The electric alternative for very simple movement and positioning tasks does not require the usual commissioning process that is needed for traditional electric drive systems, which can often be quite complex. It also offers special movement characteristics such as gently cushioned retracting into the end position, or simplified press-fitting and clamping functions.

This is quick and easy without the need for any software, computer or other accessories, because all parameters can be set manually directly on the drive. Simplified Motion Series is then connected directly to the controller, either via digital I/O (DIO) or IO-Link®, both of which are integrated as standard.

Highlights of the Simplified Motion Series

The EPCS is suitable for single linear movements in every mounting position and its smoothly running ball screw drive allows precise and rapid positioning. As an extremely cost-effective complete solution, the electric cylinder is ideally suited for applications such as positioning or clamping, distribution, sorting or ejection, and in handling systems as a simple Z-axis.

![]()

Festo Simplified Motion

Simplified Motion Series consists of different electromechanical components together with a simple and application-optimised combination of motor and servo drives, the so-called integrated drive. This solution does not require an external servo drive. The electric alternative for very simple movement and positioning tasks does not require the usual commissioning process that is needed for traditional electric drive systems, which can often be quite complex. It also offers special movement characteristics such as gently cushioned retracting into the end position, or simplified press-fitting and clamping functions.

Commissioning

This is quick and easy without the need for any software, computer or other accessories, because all parameters can be set manually directly on the drive. Simplified Motion Series is then connected directly to the controller, either via digital I/O (DIO) or IO-Link®, both of which are integrated as standard.Highlights of the Simplified Motion Series

- Simplified functionality for simple movements

- A variety of movements with different mechanical systems

- Integrated products eliminate the need for a control cabinet

- Quick and easy commissioning without software

- No special expertise required for commissioning

- Digital I/O (DIO) or IO-Link® integrated as standard

Electric cylinder EPCS

The EPCS is suitable for single linear movements in every mounting position and its smoothly running ball screw drive allows precise and rapid positioning. As an extremely cost-effective complete solution, the electric cylinder is ideally suited for applications such as positioning or clamping, distribution, sorting or ejection, and in handling systems as a simple Z-axis.

- Three sizes with a max. stroke of 500 mm

- Simple and cost-effective position sensing with proximity sensor, flexible, reliable and quick to mount, can be retrofitted or repositioned at any time

- Optional: ducted compressed air compensation prevents particles or moisture from entering and particles leaking into the environment

- Unique "one-size-down" assembly system in conjunction with the spindle and toothed belt axes ELGS-BS/-TB

- The motor can be rotated 4 x 90° – this can be modified at any time

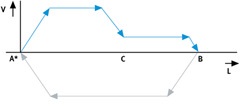

Basic profile for movement between two end positions: with speed control

Expanded movement profile for simplified press-fitting and clamping functions: with speed and force control

You might also be interested in this:

Festo servo drive

Read further

Servo drive CMMT-AS/CMMT-ST and servo motor EMMT-AS. Complete drive system, consisting of servo drive and servo motor, with seamless connectivity in hardware and softwar

Festo DGST

Read further

Small but strong: the DGST is the smallest of its kind and the shortest slide drive on the market. However, it is strong when it comes to precision, forces, motion control, durability and reliability. For maximum torsional rigidity, the yoke and slide are a single part and the sensors and cushioning are fully integrated.

SKF Blue Line

Read further

Food grade is commonly considered to be the equivalent of having food-grade seals, food-grade lubricant and corrosion-resistant bearing units.

VLT Midi Drive FC 280 AC drive delivers precise and efficient motor control for machine builders in the food and beverage, material handling, and processing industries. It is strong on control performance, functional safety, and flexible fieldbus communication. It’s also an easy retrofit for the VLT 2800 in established plant or machinery concepts.

Check out our other success stories:

-

Sekisui AlveoRead moreFoam producer Sekisui Alveo has a large factory in Roermond. To support production and maintenance, warehouses and distribution points with thousands of different items are spread across the various halls. Think spare parts, personal protection equipment and consumables. The company cooperates intensively with itsme for management, such as recently with the step-by-step introduction of vendor managed inventory (VMI) for the grab stock of mechanical items.

-

IECRead moreTo control the expansion of a silo park, engineering & construction company IEC called on Breemes. Being involved in the engineering from the beginning, the electrical service provider was able to make smart proposals for both the low-voltage part and the PLC control. ‘We have always been able to find each other well and when changes occurred, we were quickly on the same page with Breemes.’

-

Heliox - Charged for DeliveryRead moreHeliox, a developer and manufacturer of charging systems for electric buses and trucks, was already working with itsme when production still took place in the Netherlands. Today, production has shifted to Slovakia, Portugal, and Moldova, and is also happening in the US. itsme remains the “irreplaceable” partner for the supply of electrical components and cable harnesses.

-

BLOK System SupplyRead moreBlok System Supply and itsme have maintained an intensive relationship for many years. Early last year, this was further deepened with electronic data exchange via the Smart Connected Supplier Network. ‘It saves an enormous amount of time and reduces errors. We always have real-time information automatically.’ However, time for personal contact is not saved. ‘That is precisely what makes itsme a very nice party to work with.’